Vintage machinery doccumentation

With a background in milling and baking, coupled with SolidWorks CAD and traditional carpentry skills, Director Adrian Marshall also spends time restoring and doccumenting 'vintage machinery'.

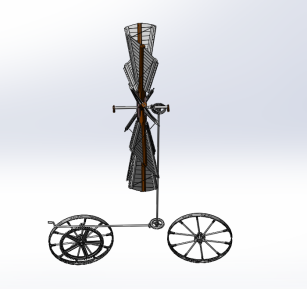

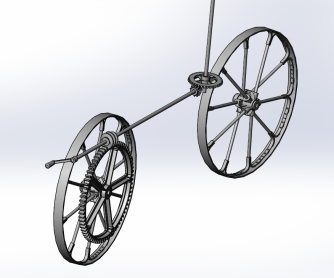

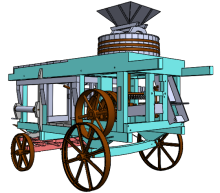

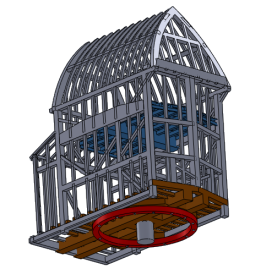

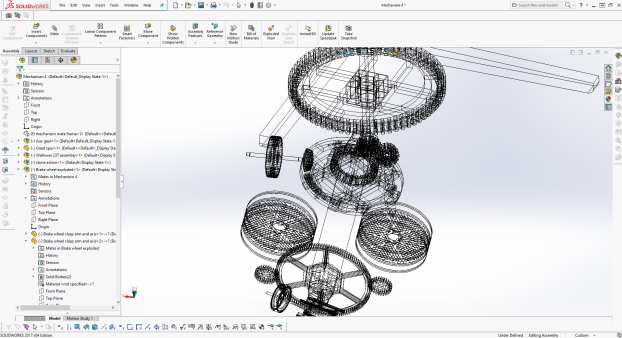

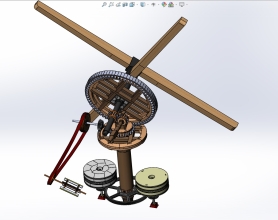

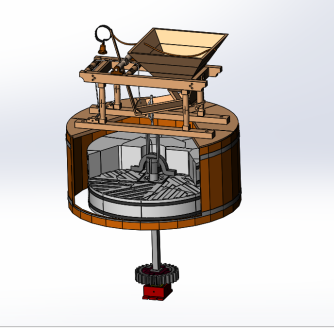

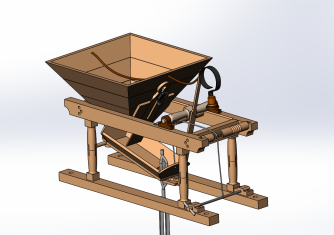

As well as rebuilding Chinnor postmill,he has made detailed measurements and animated CAD models of a highly unusual mobile mill, and a grain winnower, as key elements of their respective restoration programs.

His work in recording these machines has been reported in the SPAB 'Mill News' periodical

(151 & 153)

Doccumenting vintage machinery and creating accurate animations of their operation is highly specialist work, and helps re-discover, record and disseminate the expertese of the machinery builders of the past.

Adrian is also able to advise on experience (joys and trials) of nearly 30 years of mill restoration, having been a volunteer, and laterly the project leader, on the rebuilding of the demolished Chinnor post mill, with a key role in re-discovering the mill's detailed construction by analysis and interpretation of its photographic archive

Photo: Thame Gazette

Adrian Marshall back row on the right

Chinnor Windmill walk-by, and up the ladder

Chinnor Windmill fly-by, and in the roundhouse

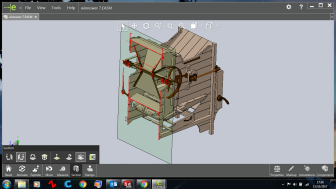

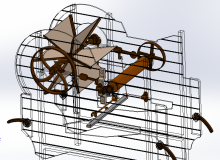

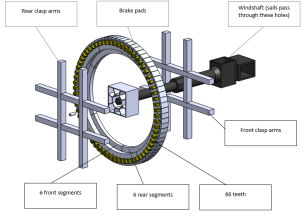

The internal mechanism of Chinnor windmill has also been drawn up to aid the restoration, and to show how the mill works.

The wind force against the canvas sails (not shown) turns them and the large angled brake wheel, which meshes with the wallower gear which transfers the motion to the lower floor via a vertical drive shaft, where the stones pick it up off the spur gear.

Chinnor mill has an auxiliary gear under the wallower which generates a high speed drive via a belt to the flour dresser (a rotary sieve) at the rear of the mill.

Lying alongside the main windshaft there’s a secondary shaft around which the sack hoist chain runs, to lift bags of grain to the top of the mill

The mill is automatically kept pointing into the wind by a highly geared drive onto the 'fantail' carriage