Steerable rollers

Up until now every roller has just conveyed product forward, but with Crafty Tech’s ‘Steerable Roller’, product can now be selectively steered sideways whilst crossing a roller bed.

This can be used to route products to multiple machines on demand, to diverge or converge product centres, correct upstream belt wander, or bias product to one side for example to optimise spiral freezer loading.

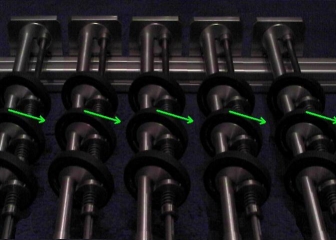

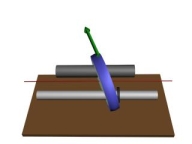

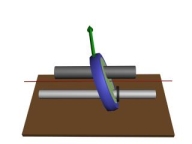

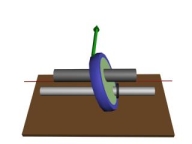

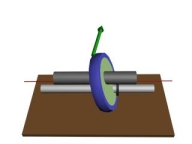

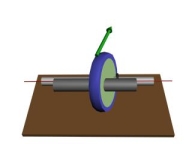

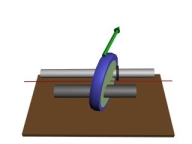

Each steerable roller is made up from a number of rigidly fixed inclined wheel hubs, each with a rubber tyre running freely around its edge, driven via a friction drive by a common offset drive shaft.

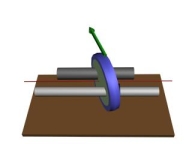

Real-time steering is achieved by simply rolling the whole roller assembly slightly about its longitudinal axis, so that the orientation of the inclined wheel hubs changes, altering which part of the tyre’s motion is on the top of the roller (the part that actually touches the product)

For example if the roller is turned so the wheel hub is leaning precisely to one side, then the tyre will drive straight ahead, but for other roller angles, the top of the tyre will produce a drive directed at an angle to the flow, as the series of pictures show.

By assembling rollers with appropriate wheel inclination angles, a variety of roller beds can be configured that will for example switch from steering to the left to the right, from converge to diverge, or to give an adjustable bias of product distribution to one side of a process (for example to achieve optimum loading of spiral freezers)

The ‘’Steerable roller’ was one of a number of patented product handling systems launched by Crafty Tech at the ‘Excellence in Food Manufacture 2004’ Conference at PERA in October.